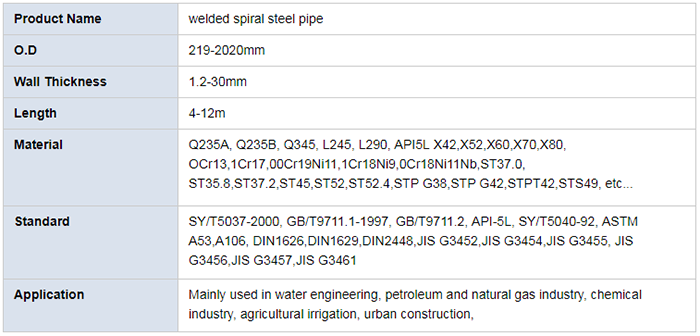

Welded steel pipe can be divided into straight seam welded pipe and spiral welded pipe according to the form of weld.Classification by production method: Process classification - arc welding pipe, resistance welding pipe, (high frequency, low frequency) gas welding pipe, furnace welding pipe.Straight seam welded pipe production technology is simple, high production efficiency, low cost, rapid development.Spiral welded pipe generally has higher strength than straight welded pipe. Welded pipe with larger pipe diameter can be produced from narrow blank, and welded pipe with different pipe diameter can also be produced from blank of the same width.However, compared with the straight welded pipe with the same length, the weld length increases by 30~100% and the production speed is lower.

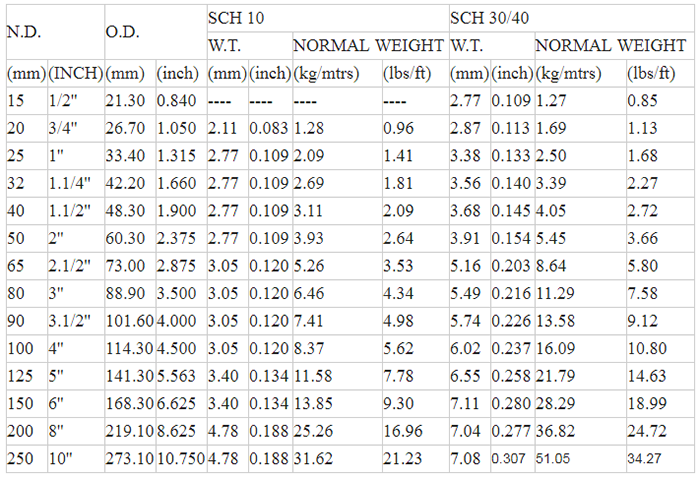

Straight seam welding is used for small caliber pipe, while spiral welding is used for large caliber pipe.According to the shape of the steel pipe end, it can be divided into circular welded pipe and special-shaped welded pipe (square, rectangular, etc.).According to different materials and uses, it can be divided into welding steel pipes for mine fluid transport, galvanized welded steel pipes for low-pressure fluid transport, and electric welded steel pipes for belt conveyor roller.According to the current national standard specifications size table, according to the outside diameter * wall thickness from small to large sort.

Jinjiang Changjiang Steel pipe Industry Co., LTD. Specializes in the production and sales of straight seam welded pipe, Fujian seamless pipe, Fujian spiral pipe and shelf pipe, welcome to inquire: 86-0595-82151777